Research & Development

Social Responsibility

Standards Formulation

Products

Advanced Amorphous Technology

Founded in 2016, AAT Amorphous is a professional hi-tech amorphous company engaged in R&D, manufacture, and distribution of Amorphous and latching relay related products. By adopting this philosophy, we are constantly striving to become R & D and production basement of the country and even the world for advanced materials, to be a high-quality supplier for amorphous and latching relay materials.

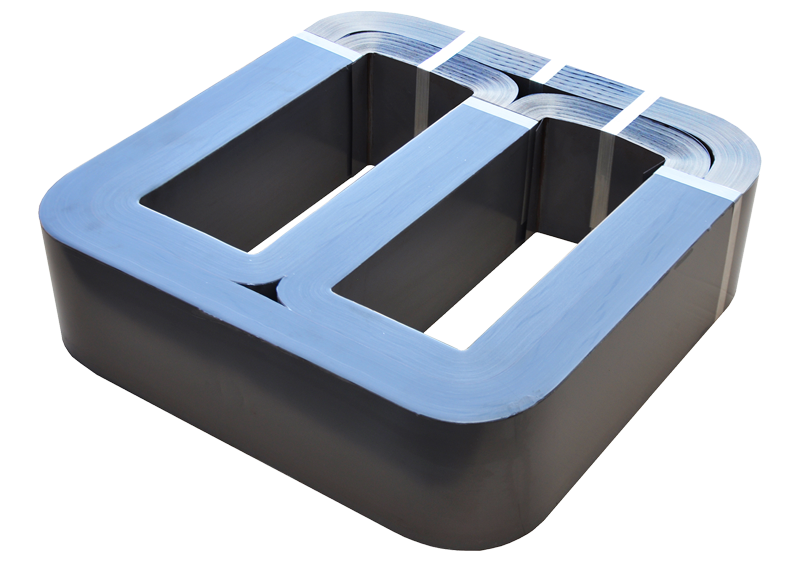

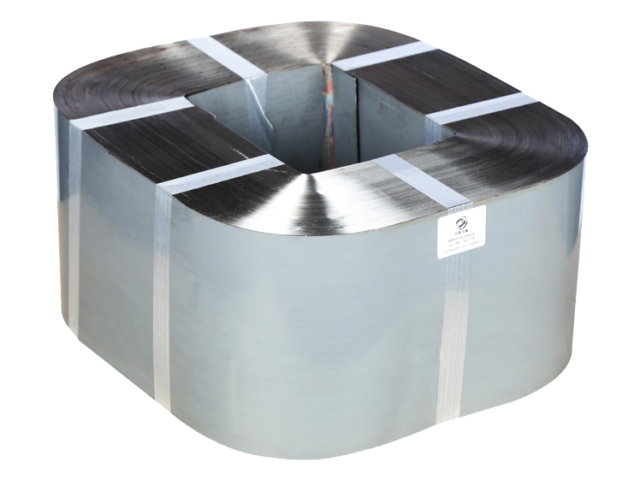

Advanced Amorphous Technology (AAT) produces distributed gap wound amorphous cores for the distribution transformer industry. AAT manufactures amorphous cores as per customer specifications for ratings from 10KVA to 1000KVA from its newly established state of the art facility at Khushkhera, Rajasthan. Our works is spread on an area of 6000 sq m with built-up space of 2000 sq m.

Looking for a business partner?

Events

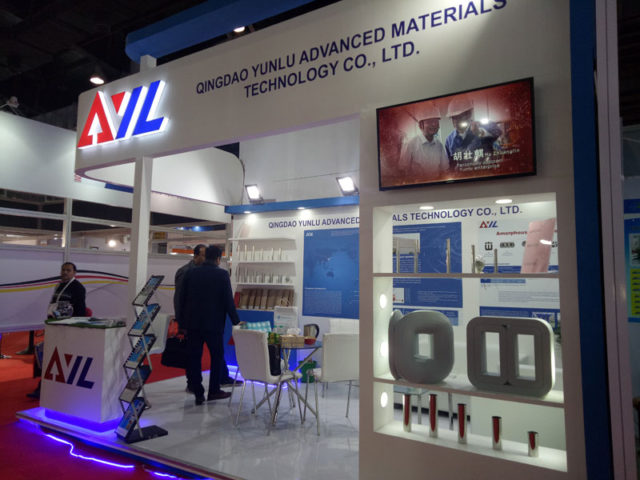

Stall No-F1, Hall No-15, at India Expo Mart, Greater Noida, INDIA, on 18th to 22nd January 2020 by our principal Qingdao Yunlu Advanced Materials Technology Co. Ltd. China

Advantages

Cost Benefit

The utility can save cost in terms of TOC; though the initial cost is little high** to minimize lifetime costs.

Proven Technology

No special technology unique required to use AMDT. Just replace CRGO-DT with AMDT

Other Features

Lower Temperature rise and Consistent Properties Flexible manufacturing process

Reduced Losses

Lower Hysterias Loss and Low Eddy Current Loss. Reliable Low loss under harmonic Power Quality

Client testimonials

Dramatically visualize customer directed convergence without revolutionary ROI. User generated content in real-time will have multiple touchpoints for offshoring.

– Lena Hammet, CLIP CEO

“Seamlessly visualize quality intellectual capital without superior collaboration and idea-sharing. Override the digital divide with additional clickthroughs from DevOps”

– Maria Kowalski, KRAFT Gmbh

Dramatically visualize customer directed convergence without revolutionary ROI. User generated content in real-time will have multiple touchpoints for offshoring.

– Steven Hammet, CLIP CEO